As formats change and the media they're recorded on ages, it becomes increasingly difficult to transfer the information off of those formats into new, more modern formats. That's basically what archival and restoration is: transferring recordings from one format to another. Usually, the transfer is from an older format on more fragile media to something newer and easier to work with.

Often a source of confusion is the .cda file. On a windows computer, when you insert a RedBook Audio CD, the tracks show up as .cda files. One might assume that these are the audio files on the disc because they are the only items that show up in the explorer window. . . that would be wrong. The .cda files are merely placeholders pointing to a place on the CD that the song starts. Think of them as what windows calls a 'shortcut'.

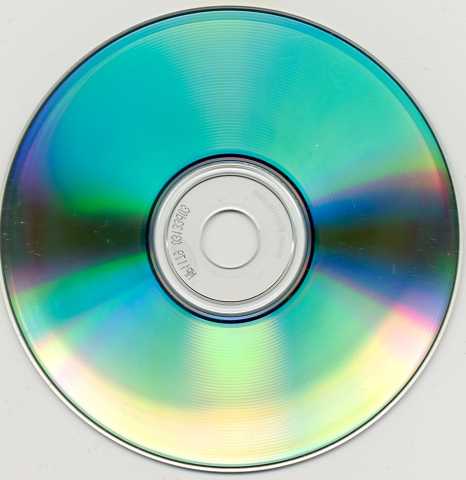

The process of creating CD's by burning blank a CD-R in a computer's disc drive or with a stand-alone unit. Although duplication yields an inferior product and costs more per unit when compared to replication, it is a better choice for small quantities (less than 300) or when a quick turnaround is necessary.

The process of manufacturing a CD where discs are created through injection molding polycarbonate plastic. These 'green discs' are then aluminum plated and another 'top coat' of plastic is applied for the label. Generally, a batch of one thousand discs is the smallest quantity that a replication plant can cost-effectively offer. This process yields a very high-quality, professional product, and is not to be confused with duplication which is of lesser quality.

A glass master is made at the replication plant in a specialized clean room, not at the mastering studio. A glass disc, 240mm in diameter and 6mm thick, is used as a substrate to 'etch' the image of the digital data as pits and lands that will ultimately be the ones and zeroes that the CD player will read as audio information. Some audiophiles insist on real-time (1x) creation of a glass master for highest audio quality.